SIZE

-

1750 L / 2 tonne nominal capacity

-

1250mm x 1190mm x 2250mm

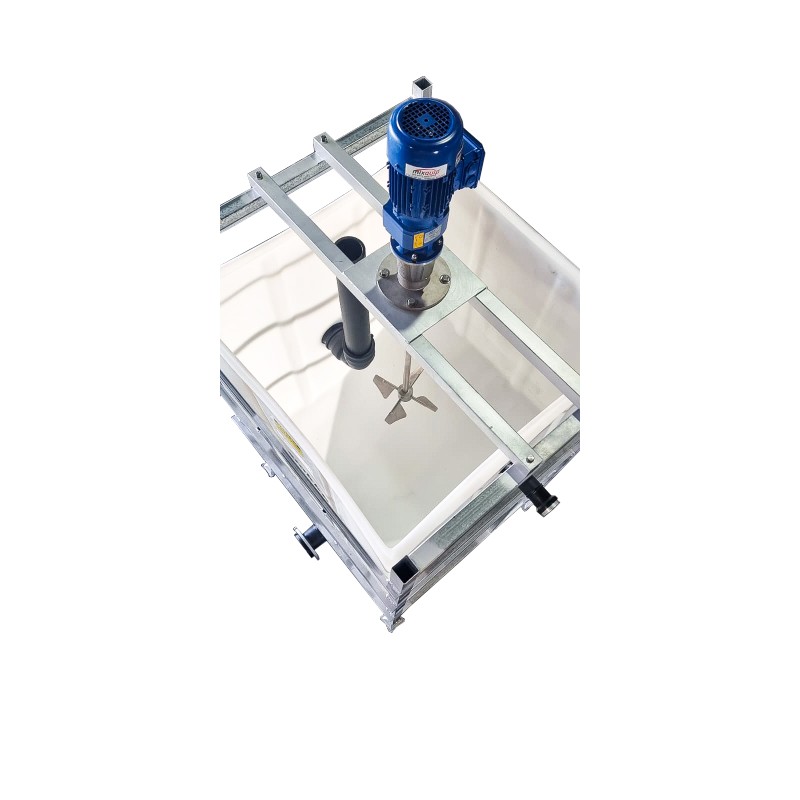

DOSING AND MIXING TANK FEATURES

- Custom fittings to suit your project

- Range of agitators & Mixers available

- Custom motor mounts

- Integrated ladder

- Complete drain base

- Fully enclosed tank with lid

- See below for additional features

Chemical Dosing Tank: Mix & Suspend Liquids

Details

| Part No. | Description | Litres | Dimensions | Overall Height (mm) | Outlet Height (mm) | Cubic Capacity (m³) | Product Details | |

|---|---|---|---|---|---|---|---|---|

| P1750DT-M | 1750L Total drain tank with mixer | 1750L / 2000kg | 1250mm x 1190mm | 2250mm | 150mm / 560mm | 1.73m³ |

|

| P1750DT-M | |

|---|---|

| Description | 1750L Total drain tank with mixer |

| Litres | 1750L / 2000kg |

| Dimensions | 1250mm x 1190mm |

| Overall Height (mm) | 2250mm |

| Outlet Height (mm) | 150mm / 560mm |

| Cubic Capacity (m³) | 1.73m³ |

| Product Details | |

| Add to Cart |

|

Features

For Dosing and Mixing Tank Contact our friendly staff today 1800 502 267.

- Custom fittings to suit your project

- Range of agitators & mixers available

- Custom motor mounts

- Integrated ladder

- Full gal steel frame

- Complete drain base

- Fully enclosed tank with lid

- Range of colours available

- 40 deg + discharge angles

- Fully enclosed forklift pockets – double option available

- UV stabilised polyethylene bin

- Built smart – will handle any situation

- Translucent bin pictured – other colours available

- Smooth internal surfaces

Why Choose Our Chemical Dosing Tanks?

The Enmach dosing and mixing tanks are designed to suspend or mix your trade waste before it is released into the treatment process. Our units can be custom built to your needs. The dosing and mixing tank comes standard with extendable legs. Access ladder integrated into the frame allowing for easy access to the top of the tank. Crafted from high-quality, corrosion-resistant polyethylene, this tank is not only built to last but also optimized for safety and ease of use. Its durable construction ensures it can handle a wide range of chemicals and liquids while maintaining structural integrity. This is just some of the unique reasons why you should choose our Chemical dosing tanks.

What is a Chemical Dosing Tank?

The dosing and mixing tank, also known as a chemical dosing tank or simply a dosing vessel, is a specialized container that can be used in various industries to prepare, store, and dispense precise quantities of chemicals or liquids. This tank was specifically designed for accuracy, safety, and ease of use in applications where precise dosing or mixing of chemicals is crucial. The dosing and mixing tank has many applications in diverse industries, including water treatment, wastewater treatment, agriculture, pharmaceuticals, food and beverage, and more.

All built and rotomolded in house from start to finish in our family owned manufacturing plant in Bundaberg QLD ensuring quality control and production schedules are under control without the need to check with outside suppliers. Full steel frame to increase the strength of the tank and also ensuring it is the most robust tank on the market, standing up to any conditions its put into. It is fully protected and can withstand rough machinery and operation.

Types of Chemical Dosing Tanks We Offer

Our chemical dosing tank is a 1750L unit with Total drain and with mixer. It measures 1250mm x 1190mm with a 1.73m³ capacity. We do have other dosing tanks, Mixing tanks and bunds available depending on your requirements.

- 110L – 500L Dosing Tank

- 230 Litre – 460 Litre

- 500L Dosing Tank

- 1600L chemical dosing tank

How to Select the Right Chemical Dosing Tank

Selecting the right chemical dosing tank involves several key considerations to ensure it meets your operational needs and complies with safety standards. Here’s a guide to help you choose the appropriate tank:

- Identify the chemicals you will be storing and dosing, including their pH, viscosity, and corrosiveness.

- Calculate the required tank capacity based on the frequency and volume of dosing needed for your processes.

- Inlet and Outlet Design choose customised inlet and outlet sizes for easy filling and dosing.

- Ensure there are proper access points for maintenance, inspection, and cleaning.

- Assess the installation site for adequate space, structural support, and access for maintenance.

If you require additional help contact us and we can assist in making the right decision for your needs.

Installation and Setup Maintenance and Care for Chemical Dosing Tanks

Order Your Chemical Dosing Tank Today. Request a quote or contact us.